Use imported optical components, good beam quality, high efficiency of Electro-optic conversion.

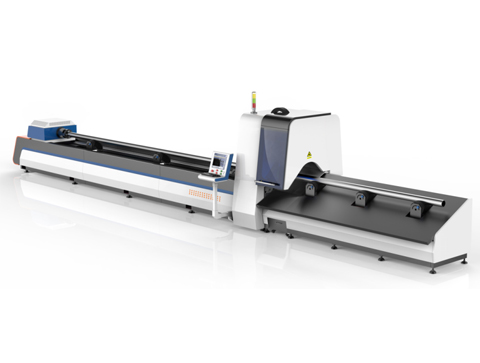

INJ-60M fiber laser cutting machine Automatic pipe laser cutting machine can easily adjust and applied to cut different shapes when cutting various sizes and shapes of pipe materials due to the use of more advanced automatic adjustment chuck. Professional pipe cutting design, applied to cut for various sizes of pipes materials. Machine front and back equipped with electric chuck, full use of pipe materials with Intelligent application. Integrated machine body, not afraid of resistance, which improved the cutting stability.

INJ-60M fiber laser cutting machine as one classic model, widely used in many common areas of our life, such as processing of stainless steel kitchenware, storage cabinet and other cabinets, is closely related to people's daily life.

| LASER TYPE : | Nd:YAG |

| LASER WAVE-LENGTH : | 1064nm |

| LASER POWER : | 850W |

| CUTTING AREA: | 6000mm |

| MAX CUTTING THICKNESS: | 8mm |

| MAX TUBE CUTTING DIAMETER: | 160mm |

| MAX TUBE CUTTING LENGTH: | 6000mm |

| CUTTING ACCURACY : | ≤0.08mm |

| MIN.CUTTING KERF : | 0.15mm |

| FOCUSING SYSTEM : | non-contact automatic tracking system |

| COOLING MODE : | water cooling |

| POWER SUPPLY : | AC 380V±5% 50Hz(60Hz optional) |

| MAIN POWER : | 21KW |

| MODEL : | GN-CTF6000-1000W |

| LASER TYPE : | Imported fiber laser source |

| LASER WAVE-LENGTH : | 1064nm |

| LASER POWER : | 1000W |

| CUTTING AREA: | 6000mm |

| MAX TUBE CUTTING DIAMETER: | 160mm |

| MAX TUBE CUTTING LENGTH: | 6000mm |

| CUTTING ACCURACY : | ≤0.08mm |

| MIN.CUTTING KERF : | 0.10mm |

| FOCUSING SYSTEM : | non-contact automatic tracking system |

| COOLING MODE : | water cooling |

| POWER SUPPLY : | AC 380V±5% 50Hz(60Hz optional) |

| MAIN POWER : | 12KW |

Stainless steel, carbon steel, alloy steel, spring steel, aluminum, aluminum alloy, galvanized steel, cincalumzalutite, copper, silver, gold, titanium and other metal

Professional used to cut thin sheet metal, in a variety of high quality 0.5 -3 mm carbon steel sheet cutting, can also be cutting stainless steel plate, aluminum alloy plate, galvanized sheet, electrolytic plate, silicon steel, titanium alloy, aluminum zinc plate and other metal.

Widely used for tubes and pipes processing, advertising trademark, advertising character, high/low voltage electrical cabinet, mechanism parts, kitchenware, cars, mechanical, metal craftwork, saw blade, electronic parts, eyeglasses, spring, circuit board, kettle, medical microelectronics, hard ware, knives tool, measurement, instrument, etc.

metal cutting, electrical switch manufacturing, aerospace, food machinery, textile machinery, engineering machinery, locomotive manufacturing, agriculture and forestry machinery, elevator manufacture, special vehicles, household appliances, tools, processing, IT manufacturing, oil machinery, food machinery, diamond tools, welding, welding gear, metal materials, decoration advertising, laser surface treatment of foreign processing services, such as all kinds of machinery processing industry. Our fiber laser cutting machine's